Updated on Dec 27, 2024 - Construction telematics uses cellular/GPS IoT technology and onboard diagnostics data to track equipment location, usage and health. Cellular asset trackers collect and send this data from construction equipment to a software platform for interpretation in meaningful ways for construction businesses. Telematics data includes location, speed, engine diagnostics, fuel usage and other vital asset data that contractors can use to track and manage equipment operations.

Telematics solutions for equipment can be used to track and monitor any registered construction asset. This includes everything from heavy machinery to small tools, all in real-time. This technology makes construction equipment management easier and more efficient, and the data collected more accurate and complete.

How? In this blog post, we will explain the technology behind construction telematics and the benefits of using telematics. We will also share real customer examples and their return on investment (ROI).

The Technologies of Construction Telematics Software

First, let’s talk a little more in detail about how construction telematics works. Integrated construction software uses four primary components to gather and deliver data:

- Location-based services (LBS)

- Vehicle telemetry

- Equipment usage sensors

- Onboard diagnostics systems

Although many of the individual technologies used in telematics solutions predate the Internet of Things (IoT), modern construction telematics is an IoT solution. Construction telematics software takes advantage of today’s wireless internet connections to transmit data faster and more efficiently.

Location-Based Services for Construction Telematics Software

One main use of construction equipment telematics is to help owners and site managers track their equipment in real-time.

Modern construction telematics uses location-based services (LBS). They rely on local cellular networks and global navigation satellite systems (GNSS) for positioning. Generally, these systems are available to tracking devices to establish position:

-

- GPS

- GLONASS

- Galileo

- BeiDou

These systems are maintained by the USA, Russia, The EU and China respectively.

After finding the location (position) using GNSS, the tracker uses mobile internet to send the data to a database. This system implements the LBS functionality, providing information to the equipment operator or a manager.

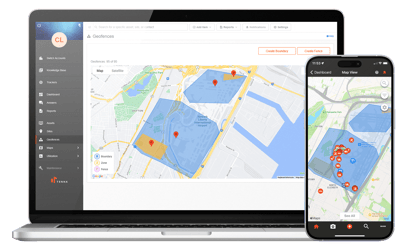

This technology gives you real-time information on every connected asset while it is in use. For example, an equipment owner can examine a map of a job site and identify the location of every tagged asset there. They can also see if certain assets enter or leave a specific area using geofencing.

Telemetry and Equipment Usage Monitoring

Another key use for construction telematics is to read onboard telemetry, which helps send accurate data about equipment or vehicle usage. This data comes from monitoring vehicle systems and parameters via CAN bus. Contractors can use this data to report on vital stats for each vehicle or piece of heavy equipment.

GNSS, like those used by LBS, can estimate how fast a moving object is going. However, it cannot give jobsite managers details about how vehicles are used. It only provides data based on location. Usage patterns, however, can be inferred by the locations of assets throughout the workday.

IoT telematics trackers can provide:

-

- Trip cycles and usage data

- Current speed and idling time data

- Speed, acceleration, and braking data

- Fuel consumption and estimated emissions data

- Seatbelt detection and usage statistics

- Diagnostic trouble codes and fault codes

- Power Take-off status

A subset of this functionality is monitoring equipment health. Telematics solutions can communicate with on-board diagnostics systems to do this.

The equipment’s computer system collects on-board diagnostic data. This data shows performance and possible issues and is accessed through the CAN bus port (OBD-II port in light duty equipment). Equipment managers can receive alerts and information about:

-

- Engine hours

- Fault codes

- Maintenance indicators (e.g., DEF, DPF stats, Coolant level, others)

- Fuel usage

- External Equipment engagement (PTO)

Benefits of Telematics for Construction Equipment

Construction companies can significantly benefit from using dedicated construction telematics solutions in their day-to-day field and maintenance operations as well as for better portfolio management. Here are the top reasons why you should take advantage of this technology.

Real-time Equipment Tracking

Telematics and equipment fleet management software allow contractors to track equipment with more efficiency and visibility than before. With a construction telematics solution, you can easily view each piece of connected equipment on a map and see a history of where it has been.

All you need to see equipment on your application map is a tracking device on each asset. You can install different types of tracking devices on any asset, from heavy equipment like loaders, excavators and cranes to small and hand-operated tools like compressors, power drills and jackhammers.

Different types of asset trackers provide different data, depending on the technology they use and the machine they are installed on. This allows for a custom solution for each asset type.

Using equipment location tracking devices helps you monitor your fleet, which reduces the risk of losing or misplacing assets. It also reduces extra costs from unnecessary replacements or rentals. This helps contractors make the most of what they already own.

Another leading use case for location tracking is the ongoing issue of construction equipment theft. Equipment managers can track where all connected equipment is at any time. They can also set up alerts for when assets leave the job site.

Site managers can use geofencing functionality to make a virtual zone on the map. This zone is usually set to match the geographical limits of a project site. It can also apply to other areas of equipment operation or storage, such as a laydown yard.

When connected equipment leaves the geofenced area, the linked construction software can alert the manager right away. This helps improve construction security.

More Efficient Equipment Maintenance Processes

Construction equipment telematics software supports equipment maintenance by enabling contractors to automate maintenance intervals on time or usage-based scales according to tracker data. This helps contractors gather data on asset health and use. They can easily schedule custom maintenance for each asset type. They can also act quickly when they need to make repairs or handle unexpected maintenance.

Telematics software designed for construction businesses helps contractors keep track of equipment maintenance. It allows them to log maintenance events easily, create maintenance requests and work orders, and track the progress of maintenance activities.

If an asset shows an engine or subset fault code, the telematics software can send an instant alert, prompting equipment managers to issue service requests. Leveraging construction telematics to optimize equipment maintenance helps minimize downtime and keep productivity up.

REAL Contractor Use Case: D. Guerra Construction

REAL Contractor Use Case: D. Guerra Construction

Watch how this contractor saved $20,000 in repair costs by keeping up with preventative maintenance and avoiding unnecessary fixes through telematics data.

Reduce Equipment and Vehicle Operating Costs

While investing in a telematics solution for your construction equipment is a financial commitment, using its features can help contractors significantly reduce equipment ownership and operating costs in many practical ways.

For example, monitoring your engine idling and speeds can help determine if assets are burning excessive fuel. Did you know that driving just five mph over the speed limit can lower your fuel efficiency by 7% to 14%? With a telematics system, you can track fuel usage both in-trip and while idling. This helps you know if your workers are operating your equipment efficiently.

From maintenance, safety inspections, proper utilization and simply knowing what you own, contractors can use telematics data insights to make better decisions around how they operate and maintain their fleet in more cost-effective ways.

Check out our post 5 Ways to Lower Equipment Operating Costs to learn more ways construction technology can help.

REAL Contractor Use Case: Boudreau Pipeline Corporation (BPC)

REAL Contractor Use Case: Boudreau Pipeline Corporation (BPC)

See how this contractor tracked usage data to make better choices about asset assignments. As a result, they reduced idle time by 397 hours and saved between $15,000 and $19,000 each month.

Compliance with Fuel Tax Regulations

Construction telematics can help you calculate the fuel tax you must report to the federal government by following the rules of the International Fuel Tax Agreement (IFTA). This is extremely helpful when driving commercial vehicles in different states. It also helps when moving equipment across state lines for projects.

You can use GPS asset trackers to determine where your trucks and vehicles are accruing IFTA miles. Construction telematics systems make it easier to collect, analyze, and track miles driven by state, region, or province. Systems, like Tenna, prepare useful reports with this information for accounting purposes and federal fuel tax reporting.

REAL Contractor Use Case: Environmental Products Group (EPG)

REAL Contractor Use Case: Environmental Products Group (EPG)

See how this contractor kept up with field tracking reports and charged rental clients fuel surcharges and taxes using a construction telematics system.

Improve Operator and Driver Safety

Contractors can also learn about how each worker and equipment operator drives/operates by checking asset tracker data. This data includes acceleration, braking rates, average speed and more.

Common uses for this information include driver safety coaching by detecting potential erratic, aggressive or inefficient driving habits as well as fatigue or distracted driving and operating. Construction telematics software can incorporate safe driving promotion tools, such as driver scorecards, which allow safety and operations managers to detect inefficient or unsafe drivers and operators easily. They can then use this information to take appropriate corrective action to improve on-road and on-site safety.

Other technologies and devices compatible with construction telematics include dash cams with video telematics capabilities. In addition to promoting better equipment operation habits, telematics solutions can also protect and exonerate drivers in case of incidents where they are not at fault.

Telematics solutions can help contractors defend themselves in legal cases and minimize associated costs by combining video recordings with telemetry and location data.

Video telematics in heavy equipment can support onsite safety by facilitating better visibility for operators working in close quarters and around live traffic. Solutions like Tenna’s heavy equipment camera are uniquely useful for construction businesses looking for ways to strengthen their safety program.

REAL Contractor Use Case: Ferreira Coastal Construction

REAL Contractor Use Case: Ferreira Coastal Construction

Watch this customer story to see how this contractor improved its fleet's driver scorecards in just three months by leveraging telemetry data. Plus, see how video telematics helped exonerate a driver who was not at fault.

Integrating with Business Management Software

A construction telematics system can also help with fleet management and equipment operation outside the job site. Telematics provides key construction data that influences insights across a construction business. Construction telematics systems can often integrate and communicate with other key business systems, such as:

-

- Enterprise Resource Planning (ERP) / accounting systems

- Project operation and business intelligence Software

ERP integrations allow construction telematics data to flow into a contractor’s accounting software automatically. These integrations eliminate the need for repetitive manual data entry, reducing inaccuracies and saving time.

Project operation integrations can use construction telematics data to produce more accurate productivity forecasting and job costing.

REAL Contractor Use Case: Mladen Buntich Construction

REAL Contractor Use Case: Mladen Buntich Construction

Watch this customer story to see how this contractor successfully added telematics data from Komatsu and John Deere into their equipment management system.

How Construction Telematics is Changing the Way Contractors Operate

Telematics can serve many specific construction use cases and applications. However, the main goal of a construction telematics solution is to help contractors maximize their equipment fleet assets.

Telematics can improve operations in every aspect of a construction business that matters:

- Improved asset visibility

- Increased productivity

- Reduced total cost of ownership

- Improved worker and jobsite safety

- Increased cost control

While many of the technologies utilized within a telematics system are relatively well-established, such as satellite navigation or onboard telemetry, the primary advantage of these technologies lies in the efficient interpretation and use of the data. This is only possible with software that is purpose-built for construction businesses.

Telematics data brings tremendous value to construction businesses in their day-to-day operations, forecasting and budgeting. When looking to implement a construction telematics system in your business, look for one that:

- is built specifically for construction businesses and workflows

- can allow you to track and manage your entire mixed fleet on one platform

- integrates with other key business systems your team relies on

Contact Tenna to learn more about telematics and construction technologies and visit this blog post to learn about data and analytics in construction.

About Frank Rodriguez

As the Hardware Engineering Manager, Frank works tirelessly to build Tenna’s tracker ecosystem. Leveraging contacts across industry, and vast experience in the electronics industry, Frank brings new ideas, opportunities, and capabilities to Tenna’s growing list of asset trackers, and works with Tenna’s customer success personnel to bring that value to customers. Frank has worked in a variety of technical settings in his 35+ years in electronics. Frank is a published Scientist, with 5 peer reviewed publications ranging from IoT Smart City innovation to tagging & tracking individual cells using IC chips. Frank holds 10 patents spanning a range of products and technologies, most of which resulted in profitable mass market products.