Do you struggle with too many systems that don’t talk to each other?

You’re probably already using multiple construction technology systems across your business, yet if they are not integrated, getting the right information to the right people at the right time is still a struggle.

Data from FMI and Plan Grid shows that 22% of contractors saw failure in implementing a construction technology because it did not integrate well with their existing technology and software. Not integrating is among the top three reasons that contractors fail with tech (among being a poor fit with work processes and procedures, and low adoption). This proves that the need for integrated construction software is becoming an increasingly big deal for contractors.

In this post you’ll learn the benefits of integrating your equipment management system with other systems your construction business uses and learn about some of the basic software integrations for construction that are available.

What Is Integrated Construction Software, Anyway?

Integrated construction software is simply a connection between two technology systems, such as an equipment management system to a construction accounting or project management system.

Integrated construction software is simply a connection between two technology systems, such as an equipment management system to a construction accounting or project management system.

By connecting a few key pieces of data across operations and financial systems – such as equipment hours and locations – you’re actually sharing the same data in more than one system. Depending on the way the integration is set up, information may flow in one direction from one system to another, or bi-directionally back and forth between each system.

Why We Need Software Integrations for Construction

Let’s cover some of the key reasons why contractors need construction integrations.

- Eliminating inaccurate and incomplete data. We know how hard it is to stay connected to your teams in the office or the field. The folks in the office require key information and data from the field and shop, but with crazy and hectic days on the jobsite, it’s easy for the office’s needs to become an afterthought.

The result, and one of the most critical problems, is that the executive team is using old, inaccurate data to determine their plans and projections. With conflicting data and contradicting plans, you’ll stay on the hamster wheel. - Reducing wasted time. Another challenge when your systems are not integrated is the time spent on administration of systems and duplicate data entry. Time spent on repetitive data entry takes away from time that should be spent on mission critical responsibilities and valuable productivity elsewhere.

- Lowering risk for error. Not only is manual data entry an unnecessary time drain, but it also opens opportunities for human error. Keying in a “5” vs. “50” or missing a critical decimal place can throw your numbers off significantly.

- Better serving everyone’s needs. At the end of the day, not all systems can serve the needs of your entire team. Your project management, equipment management and financial management systems won’t function at 100% on their own in support of all these areas of your construction business, so the best solution for a contractor is to use the best systems for each specialty and make sure those systems tie into each other.

In summary, a non-integrated platform means workarounds and double entry to link different business units or departments (i.e., field to accounting to project management, etc.). From an operational standpoint, this results in lost productivity and inaccuracies with double entry data, confusion, lack of technology adoption and overall sunken costs.

The good news is that you can effortlessly avoid working in silos and working inefficiently by integrating your construction business systems – such as your equipment fleet management system – with ERP integrations, project operations integrations, and/or other SaaS integrations as well as AEMP/OEM integrations and other mixed fleet integrations, as they apply to your company’s “tech stack,” or the ecosystem made up of the software your teams use.

The Benefits of Integrated Construction Software

Benefits of integrating the different construction technology systems you may use include the following:

- Automation of data flow to connect systems.

When your systems are integrated, you get accurate data in whichever system you use, as opposed to translating information between the two system or referring to inaccurate information that is weeks or months old that was never updated manually. - Maximize and maintain value in systems you invested in

Integrating your software systems helps maximize productivity and extend the use of the systems you’ve already invested time and money into deploying. Integrating allows you to utilize your systems and team members to their full potential. - Maximize efficiencies and simplify processes

When your systems are integrated, you spend less time in each of them because they are talking to each other and get to spend more time doing other activities that help drive revenue. Ultimately, this makes everyone’s jobs easier.

The benefits you experience with integrated construction software have a powerful impact on the way you operate as an organization.

Equipment Management Integrations

Your equipment management system, specifically, has many integration opportunities for contractors. Information about your construction equipment fleet is valuable for your ERP and accounting systems as well as your project management and operations systems. Additionally, if you are already getting AEMP data from your OEMs, it is wise to leverage AEMP integrations to see and manage your telematics data on one platform.

In most cases, the exact integration points are unique to each system, but the different types of equipment management system integrations generally work like this:

- Accounting System / ERP Integrations: Information can flow bi-directionally between the equipment management system and the ERP, such as location, engine utilization data (hours/miles), billing information, fuel cost information, parts/labor/repair cost data and more.

- Project Operations Integrations: Information can flow bi-directionally between the equipment management system and the project operations system, such as location, engine utilization data (hours/miles), maintenance information and more.

- OEM/ AEMP Integrations: AEMP telematics data that you get from OEM integrations with manufacturers such as Caterpillar, John Deere, Komatsu, Volvo, etc., feeds one way from the OEM to the equipment management system.

Four Levels of Equipment Management Maturity

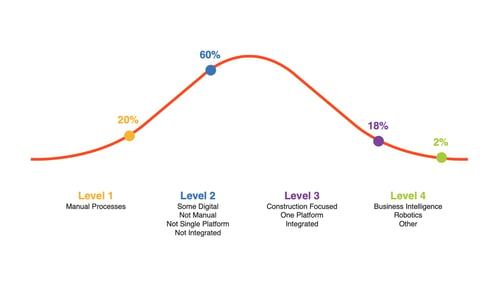

We’ve seen a few levels of technology adoption within the construction industry. Especially when it comes to contractors integrating their equipment management data onto a single platform and, further, across their existing business systems. They look like this:

We’ve seen a few levels of technology adoption within the construction industry. Especially when it comes to contractors integrating their equipment management data onto a single platform and, further, across their existing business systems. They look like this:

Level 1: Where Contractors Are Starting or Started.

Equipment Management looks like: White Boards, spreadsheets, phone calls, paper-captured utilization

Integration: Nearly none. Analog Systems

Result: Risks and pain includes inaccurate or no data leading to drains in profit and reputation (emergency breakdowns, schedule delays, underutilized assets, wasted productivity, potential safety issues) as well as the inability to attract and retain talent.

Level 2: Where Most Contractors Are Now.

Equipment Management looks like: Multiple digital systems for location, utilization and/or maintenance mixed in with some manual/paper process.

Integration: A collection of systems for equipment management makes it difficult to see all equipment and to integrate with the rest of the construction technology stack such as ERP and project operations. This is usually a “Point Solution Ecosystem” with multiple simple technology vendors. Some construction companies at Level 2 will have a more Rationalized Tech Stack – this is a fair approach, but still has risk. Also, typical in this situation, sacrificing “best-in-class” for “good-enough” solutions (jack of all trades mentality).

Result: Allows for a taste of automated data capture and an enhanced ability to focus on improved utilization, maintenance, and preventative maintenance with less time pointed at putting out fires. Typically, frustrated field and office with low visibility and understanding of multiple systems and/or “home-grown” systems that require a heavy lift in modified training, onboarding, and integrations

Note: When we polled a construction IT audience on this subject during a summer 2021 AGC conference, 92% of the audience responded that their company currently operates at Level 2.

Level 3: Where Most Contractors Should Be (The Ideal State)

Equipment Management looks like: Unified single system, fully integrated into ERP/Accounting and project operations. All field, office, and shop on same system and near live, automated data.

Integrations: Unified system, integrated platform with industry partners. This is the ideal state, with visibility and insight into all the above, seamless communication between business units and allows for operating on best-in-class applications across the board. This industry specific scope leads to a consultative approach to business, mutual up leveling and knowledge share.

Result: Equipment management is now able to actively manage by exception and to drive measurable impact to the bottom line. Reduced equipment cost can now drive directly to bottom line margin and reduced capex investment allows for reinvestment in other areas of high growth.

Level 4: Where Contractors Will Be In the Future.

Equipment Management looks like: Fully automated, live, trusted data capture on all labor, equipment, and materials which drives into a unified business Intelligence platform, enabling predictive and prescriptive analytics on all projects. Many companies will also be evolving with autonomous equipment, robotics, assistive devices, realty capture, etc., which in effect will raise the bar for the requirements in equipment management.

Integrations: Like Level 3 in general but will more often see data existing in single source outside of the ERP and project operations for display in automated business intelligence.

Result: As above in Level 3 with additional insight into discovering problems before they become problems and suggested course of action based on previous, real-world data.

How Can You Get Started With Construction Integrations?

First, reflect on where your company is today across these levels – what could you be doing differently to get to the next level?

Construction integrations across your existing business systems can ultimately take your business from chaos to calm and has opportunities to provide significant insights in the future. When considering the purchase of a new construction technology system, be sure to research options that integrate with the systems your business is already using.

If you want to learn more about how to run your business more smoothly, contact us to see how your equipment management information can integrate with your other business systems.

About Russ Young

As Chief Business Development Officer for Tenna, Russ oversees the growth strategy for the organization by working with sales, partners and customers to ensure success. Russ brings two and a half decades of experience from Google, Amazon, Oracle and FMI in best practices for technology strategy, selection and adoption. He applies his knowledge from these organizations to build awareness and provide thought leadership to the construction industry. He emphasizes the importance of technology and picking the right tool for the job.