For centuries, the construction industry has been synonymous with physical materials, skilled labor, and blueprints. But a quiet revolution is brewing, fueled by ones and zeros rather than bricks and mortar. Technology is changing how construction works, especially in the important area of procurement.

Procurement in construction has traditionally been a cumbersome process, riddled with confusion and hidden costs. Paper-based workflows, opaque supply chains, and reactive decision-making often led to delays, material shortages, and budget overruns. However, the increased use of technology can be a game changer for the procurement process. Enter the heroes of this digital transformation: construction equipment management software and other innovative technologies.

Building Smarter, Not Harder to Harness Efficiency

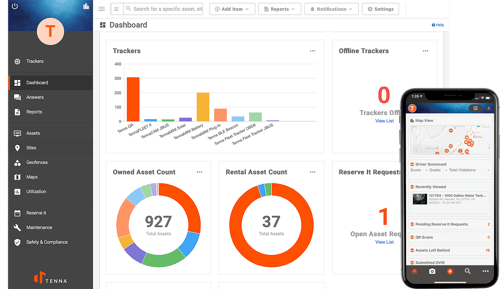

Construction equipment management software acts as the central nervous system of a modern procurement process. It streamlines workflows, automates tasks, and provides real-time data that empowers informed decision-making.

Here are just a few ways this software is simplifying procurement in construction:

Inventory management

Inventory management

Say goodbye to spreadsheets and manual counts. Construction equipment management software tracks equipment in real-time, providing accurate data on location, current use, and maintenance needs. This eliminates the risk of under-stocking or over-ordering, optimizing both cost and efficiency.- Procurement automation

Automating procurement saves time. It automates tasks like purchase orders, vendor selection, and invoice processing. This allows more time for strategic planning and managing supplier relationships. - Predictive maintenance

By analyzing equipment data, software can predict potential failures and schedule preventive maintenance, avoiding costly breakdowns and delays. - Data-driven insights

Construction equipment software gives important data on equipment use, cost per use, and project profit margin. Equipment managers and financial planners use this data to optimize procurement strategies, negotiate better deals with vendors, and improve overall project efficiency.

From Cost Drain to Profit Gain: Unlocking Hidden Value in Equipment Data

The data insights provided by construction equipment software contribute to better decision-making from procurement to profit margins. Here's how.

Optimizing Procurement Strategies

- Identify underused equipment

Analyze use data to pinpoint equipment that sits idle too often. This helps you decide whether to sell it, rent it out, or consolidate similar equipment to reduce redundancy. - Don't buy too much

Figure out the right amount and kind of equipment for projects using data and requirements. This prevents over-investment in rarely used equipment and ensures you have enough capacity for upcoming needs. - Make smarter rental decisions

Compare cost-per-use data to rental prices to determine when to own and when to rent. This can lead to significant savings, especially for infrequently used or project-specific needs. - Predictive maintenance

Utilize equipment data to predict potential failures and schedule preventive maintenance, maximizing uptime and minimizing downtime costs. This also extends equipment lifespan and reduces emergency repair expenses.

Negotiating Better Deals with Vendors

Negotiating Better Deals with Vendors

- Use your data

Negotiate better rates with vendors with equipment use data. Score lower rental fees for infrequently used equipment or discounts for bulk purchases based on projected usage. - Track vendor performance

Monitor equipment performance data to identify reliable and cost-effective vendors. This helps you negotiate better terms for future contracts with high-performing partners. - Analyze your data

Find ways to improve. Compare your equipment costs and use data to data for your region or industry.

Improving Overall Project Efficiency

- Data-driven project planning

Utilize equipment usage data and cost insights to create more accurate project budgets and schedules. This minimizes the risk of cost overruns and delays because of inaccurate equipment estimates. - Deploy equipment efficiently

Analyze project needs and use data to get the right equipment where it is needed. This minimizes downtime and maximizes productivity on-site. - Identify workflow confusion

Analyze equipment movement and use data to identify bottlenecks and issues with workflows. This helps streamline operations and improve overall project execution. - Collaboration and transparency

Share equipment data with project teams and stakeholders to foster collaboration and improve decision-making. This ensures everyone is on the same page and can make informed choices about equipment usage and procurement.

Construction companies can maximize the potential of their equipment with a data-driven approach to smart decision-making.

The Future of Procurement in Construction: A Brighter Horizon

The embrace of technology in procurement in construction is not just a trend; it's a necessity. As project complexity increases and competition intensifies, those who leverage technology to gain a competitive edge will thrive.

Imagine a future where construction procurement is not a reactive scramble but a proactive, data-driven process. Imagine real-time visibility into your entire supply chain, optimized material flow, and minimized waste. Imagine streamlined workflows, automated tasks, and empowered teams making informed decisions based on real-time data.

This is the future that technology is paving for procurement in construction. With construction equipment management software, companies will see efficiency, cost savings, greater sustainability, improved project outcomes, and a more resilient and innovative construction industry.

About Austin Conti

As CEO and Co-Founder of Tenna, Austin leverages his international experience in construction operations for civil, building, and energy projects with The Conti Group, which has built successful, reputable businesses that make a positive impact on the world in construction, engineering, renewable energy, real estate, technology, and biotech. His passion for entrepreneurship led him to create a construction technology platform built on over a century’s experience from The Conti Group.