We’ll begin by further defining construction “assets”. “Assets” is the umbrella term used within for all physical assets a contractor owns or rents. This includes, but is not limited to, heavy equipment, heavy trucks, fleet vehicles (on and off-road), mid-sized to small equipment, non-powered equipment, tools, consumables, temporary materials, and anything else used to build a project. The term can include many other physical assets a business owns but for purposes of our discussion, we are focused on the construction types of physical assets.

Our goal is to clarify what asset tracking is and is not, and how contractors can identify and benefit from the best asset tracking system based on their unique business operations and needs. In this post we discuss the tracking of physical assets (vs. digital or other types of assets) and are focused specifically on asset tracking for construction.

What is Asset Tracking?

What is Asset Tracking?

By now, whether you are using it or not, most contractors are familiar with the concept and trend of asset tracking.

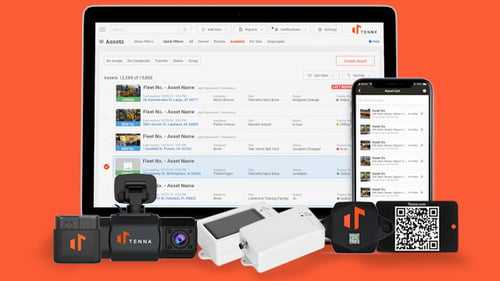

But as a quick refresher, plain and simple, asset tracking is a process where you track the location of your physical assets using hardware devices such as GPS, Bluetooth low energy (BLE), QR codes or RFID tags that report asset information to a central location within an asset tracking software. We’ll get more into these asset tracking devices and these central locations, often referred to as systems, solutions, or “platforms” below.

Asset tracking is a key part of the overall construction asset management process. This is where the lines sometimes get blurred. First you have asset tracking, and then you can have asset management.

Asset tracking is a sure use case, but if you own and work with construction assets, you know there is a lot more you need to know about them than just where they are. More on that below.

The “Next Wave” of Asset Tracking Technology

Since asset tracking technology has been around for several years now, we are at a point where can consider ourselves in the next wave. The technology is expanding and improving, and the providers have had ample time to build a product that works for their customer base.

Another result of years passed is that contractors using asset tracking successfully now understand that it’s no longer a “nice to have” but rather an integral part of their successful business operation.

For contractors that are using asset tracking systems or are ready to pull the trigger and adopt, its important now more than ever to make sure they are embracing the right asset tracking tool for their business, and not just a generic product with a familiar name that is not focused on their needs.

Contractors looking for asset tracking systems today need a focused, consolidated asset tracking and management system. Let’s break that down quickly:

- Focused: If you’re a contractor, your asset tracking system should be built for the construction industry. If an asset tracking provider serves construction among ten other industries like education, healthcare, restaurants and more, their sole focus is not on you, and you deserve better. The result is that the product does not fully fit your use case. When a provider is not fully focused on construction, they do not understand the specifics and nuanced solutions the industry needs in an asset tracking system. Entrusting the tracking and management of your assets in an unfocused solution is like using a screwdriver when you need a hammer.

- Consolidated: Contractors have mixed asset types in their fleet. If you have a tool tracking system for your small assets and handhelds, a fleet tracking system for your trucks and vehicles, and still another GPS tracking solution for your heavy equipment, you’ve probably realized at this point that your tech stack is complicated, and your data is scattered. Your equipment manager and other key personnel are spending time in multiple systems to get the answers they need and spending even more time to aggregate that data together to see the big picture. Asset tracking systems built for construction are available for you to track all these construction asset types together in one place, simply and efficiently.

These two points are important to consider before we dig into the details of asset tracking and management systems.

How are asset tracking systems useful?

The concept of asset tracking is undoubtedly extremely valuable for businesses that rely on physical assets to perform their operations and core functions.

Construction is one of the industries where that matters significantly. Asset tracking enables contractors to get more out of their mixed fleet assets by providing 24/7 visibility into when, where and how the field uses them, in addition to who used them.

Asset Tracking Systems Should Answer These Questions:

- Who: This pertains to your employees who use your assets.

Who used the asset last month? Who operated it on that jobsite? Who reserved it for that jobsite? Which mechanic is performing maintenance on it? Who is assigned to it now? Who is operating it at this very moment? - What: This includes the details of each asset for easy reference and accessibility, such as category type, year, make, model, Serial Number/VIN, etc.

Where is that exact PC400 I’m looking for (fleet number 1929)? How many D6 dozers do I have? Which generators do I have available? How many road plates are in the yard? Which assets are older than 2005 and need maintenance more frequently? What model numbers require special parts? What assets are tracked with GPS trackers vs. BLE trackers? Which assets in my fleet are rented vs. owned? How long has that rental loader been billed to that job? What project has the highest rental spend? What’s in use vs. available? - Where: Quite often the biggest pain point is usually knowing where the dang thing is.

Where was that asset used? Where is it now? Where is it going? Where has it been requested? Is it at a jobsite? In the shop? Hiding in the yard? On a shelf in the warehouse? Driving to lunch? Parked in the office lot? It was just there yesterday! Where is that bucket? Where are all the ladders?! - When: Tracking the history of your asset activity is helpful for billing, reporting, forecasting, maintenance and more.

When did it enter that jobsite? When did it leave? When did it return to the yard? When will preventive maintenance reminders be triggered? When was it serviced last? When did we buy it? When was it rented? When was it utilized this month? When did it last run? - Why: Details and visibility are tremendously helpful when communicating asset needs between departments or locations.

Why has this maintenance request been submitted? Why is this specific asset needed on that particular jobsite? Why isn’t that asset working on this jobsite? Why did that accident happen? Why are there so many hard braking events? Why is this tracker offline? Why have we rented this asset type so frequently…should we buy one? - How: Understanding how your assets are used is key to measuring its usefulness in your fleet.

How frequently is this machine requested on jobsites? How often is it utilized when it gets there? How often does it typically run at a time? How long is each cycle? How frequently does it need maintenance? How frequently has it broken down? How many assets are down for maintenance now?

These questions are best answered when the asset tracking solution provider anticipates those questions, understands the data needed to aggregate and answer them and tracks all the data needed to support those insights fully across your fleet.

We cover specifics on asset tracking devices and software below, and additional asset tracking FAQs.

Asset Tracking Hardware Devices

Asset Tracking Hardware Devices

At its core, asset tracking helps you locate your assets so you know where they are and the related insights that stem from that basic yet critical information. As noted, this is a huge pain point for many contractors and one that asset tracking technologies easily solve, provided you have the right hardware that delivers reliable data and can withstand the beating of being attached to your assets while asset trackers perform their daily duties and get knocked around onsite.

Main Types of Asset Trackers and Tags:

- GPS Trackers: These use cellular technology and are a great solution for tracking heavy and mid-sized equipment as well as trucks and vehicles.

Note, as of this writing (early 2021), the GPS microchip that the world is waiting for has unfortunately not yet been developed. No doubt about it, GPS trackers are certainly getting smaller and smaller, but they are not yet the size of your fingernail as some may expect. - Fleet Trackers: A type of cellular GPS tracker, fleet trackers track your fleet vehicles plus light and heavy-duty trucks.

- Safety Cameras: This type of asset tracking device is more advanced and works in conjunction with a GPS fleet tracker to captures valuable video footage of on-road safety events and incidents.

- BLE Beacons: These trackers use Bluetooth Low Energy (BLE) so your assets can be picked up by a reader or hub when located within a certain proximity. These readers/hubs may be other types of trackers or a mobile device with a tracking app on it.

- QR Tags: These asset tracking tags us QR codes that are etched onto aluminum tags or sticker labels and manually scanned to capture location and other details. QR codes are highly durable and great for tracking small items but do require the manual effort of scanning and are not automatic.

- RFID Tags: This solution is good for warehouse and inventory control and works like an EZ-pass to capture assets that pass by RFID readers.

Note, a lot of contractors look to do their asset tracking with RFID but, frankly, its not an optimal solution. The tags aren’t typically durable enough to withstand harsh construction environments and BLE or QR is usually a better choice.

Asset Tracking Software

Once you’re confident that an asset tracking provider has durable and reliable hardware to collect data from your assets in the field, you want the peace of mind that the software that your asset tracking data feeds that can interpret the data for you.

The right provider understands this for the construction industry. Contractors don’t need an overwhelming data dump. A good asset tracking software solution interprets and buckets this data into valuable insights for you so you can easily find and digest it. It shouldn’t take you more time to figure out what to do with your data. If your solution provider does not know what you are looking for, they will not organize your data in a way that is useful for you.

Great asset tracking providers also know that most contractors need more than just location tracking. It’s about asset management and optimization. While knowing “where are my assets” is a huge pain point, there is so much more to know about your assets that is useful to other areas of your business. These tracking partners provide this for you, going beyond tracking. We’ll get into some specific hazards to watch for related to provider mismatch a little later.

Asset Tracking Data

Asset Tracking Data

Businesses that do well and operate successfully function like a well-oiled machine. The different elements of a business connect and communicate with each other. Contractors that have success in asset tracking are thinking and acting way beyond just tracking. They are focused on asset management which starts by connecting their asset data (via asset tracking hardware) to their team members that need it.

Different types of Asset related data (outside of solely location) play a huge role in supporting other roles and departments in a construction company outside of just the field and project teams. Learn 3 reasons why effective managers use asset tracking.

Teams and departments that benefit from asset tracking data include:

- Shop Personnel: It helps with regularly scheduled and ongoing preventive construction equipment maintenance, as well as repair and replacement needs, and scheduling downtime around required uptime.

- Accounting Staff: Asset tracking data can benefit the accounting team with accurate cost and billing data.

- Project Staff: The project management teams in the field use the data to help with projections and scheduling meetings when they know what’s available as well as manage rentals.

- Equipment Management: The Equipment department staff obviously needs operational asset data to support active projects in the field, but as the “owners” of your company’s equipment, they benefit from on-the-spot knowledge to quickly review updates, status and progress regularly, and gather data for the executives. How many times has your CEO or CFO reached out for data and you’ve had to scramble to find, assemble and check it so that it’s right, eating into the time you were supposed to be using for other work?

- Executive Team: Aggregated data helps the executive team make key business decisions. Good asset tracking providers know what those execs are looking for and can provide that aggregated data easily so it can be called upon for quarterly or annual reporting and board meetings.

When the whole team is using your asset tracking data, you’re getting more value out of the system with a broader reach throughout your organization.

Better interaction and use of your data can also shed light on how the asset tracking system is truly doing its job to provide you the ability to efficiently manage your mixed equipment fleet. This ultimately saves costs for your business and helps measure any key performance indicators you’ve set around recognizing a return by using the system.

Asset Tracking Systems for Construction vs. Other Industries

Now that you have an idea of how asset tracking works and how you can expect to use an asset tracking system optimally, we’ll get into how to go about finding an asset tracking provider that will work for your business and be adopted by your teams. (You may notice a theme developing here.)

There are tons of asset tracking solutions out there today. It used to be difficult to weed through all the noise and find the right partner, but as asset tracking has evolved into the next wave (in general and for the construction industry), there is one thing today that fortunately is crystal clear:

If an asset tracking provider does not focus solely on construction, save yourself the trouble and eliminate them from your evaluation.

Why do we say this? Well, asset tracking systems have been around for several years (remember, we’re in wave two now). A lot of the early-adopter contractors have been burned by using systems that were either not mature enough or not built for their industry.

We’ve heard this firsthand from several contractors that we’ve worked with, and it’s a common theme highlighted across industry conversations. You’ve probably heard it from some of your contractor peers as well, so this shouldn’t come as a huge surprise.

When using an asset tracking provider that doesn’t understand their industry, here are the main issues contractors run into every time:

- The hardware is not reliable.

- Not built for construction environments

- The data is a jumbled mess, there is too much of it and it doesn’t tell you what you need to know.

- This is just overwhelming. Great, you have the data, but what does it mean? How do you use it? This is again is why it’s important to realize it’s not just about an asset tracking system but rather one that is built with a focus on construction and knows what data matters to the contractor so they can manage their assets.

- Your accounting teammates might be Excel wizards, but your equipment managers might not want to spend hours sorting through data and figuring out how to work with it so that it makes sense or gives them what they are looking for.

- Implementation is done by mechanics that don’t know how construction equipment works and is sometimes outsourced by third parties that don’t even work with your provider.

- And expecting to get an implementation schedule on the books that doesn’t interfere with an active jobsite’s critical path activities? Forget about it. When you partner with a regular tech tracking company, you’re on their schedule. If that interferes with the concrete pour you’re doing on that bridge deck next week, too bad.

- Customer service doesn’t know what you need.

- Sure, the customer service rep might know how the product works, but when you are finally able to get a hold of them and ask them how to use the product to get what you need, you’ll find yourself frustrated and disappointed because the product doesn’t actually do what you need it to.

In wave two, you have options now, and solutions built specifically for construction.

A construction-specific asset tracking system can be a real help in many ways, but here are the top five benefits:

- You get the right, reliable tracking device hardware for your machines and jobsites.

- Your pain points are solved for them in the software.

- You get data that matters and means something to you.

- You build relationships with service managers who how to talk to your guys and gals.

- You schedule implementations and installations with mechanics that know your machines and work with your tight construction schedule instead of interrupting it.

Conclusion & Key Takeaway

That was a light overview on what to think about when exploring asset tracking solutions. For more info on asset tracking technology, features, use cases and costs.

Construction businesses should look for focused, consolidated asset tracking and equipment management solutions that take them beyond tracking and enable them to manage their fleet in 2021 and into the future. You can’t have total success in your asset tracking and management efforts without the key fundamentals of focus and consolidation in your system.

We welcome you to Book a Demo to continue this discussion as it relates to your unique construction equipment tracking and management needs.

About Russ Young

As Chief Business Development Officer for Tenna, Russ oversees the growth strategy for the organization by working with sales, partners and customers to ensure success. Russ brings two and a half decades of experience from Google, Amazon, Oracle and FMI in best practices for technology strategy, selection and adoption. He applies his knowledge from these organizations to build awareness and provide thought leadership to the construction industry. He emphasizes the importance of technology and picking the right tool for the job.