Construction technology is the rainstorm contractors need. Rising costs, worker shortages, and increased demand has created uncertainty for modern construction companies. However, new technology offers solutions.

In 1996, the IBM supercomputer, Deep Blue, challenged grandmaster Gary Kasparov to a chess match. This game was more than a worldwide spectacle - it was a historical landmark in technological advancement.

In many ways, project managers and construction leaders are like chess players, bending their minds to calculate present and future decisions. What if, instead of battling technology, as Kasparov did, construction teams and technology joined forces?

Let’s find out.

Construction Technology – Past and Present

What is construction technology? Construction technology, also known as contech, refers to any equipment, software, or method that improves the construction process. Contech could include worksite safety sensors or mobile apps that track equipment. As you can see, the field is broad.

Almost a century ago, in 1923, James Cummings was credited with designing the first tractor-powered bulldozer. Fast forward to 2021, and we have robotic excavators using AI technology to move the soil.

Within the past ten years, billions of dollars have funneled into developing innovative construction technology. However, this isn’t the end – the industry is growing.

New trends in construction technology aim to fill the cracks between rising costs and more demand. Let’s look at several forms of smart construction technology and telematics software to gain a clear understanding of where the ship is headed.

Construction technology examples include:

Construction technology examples include:

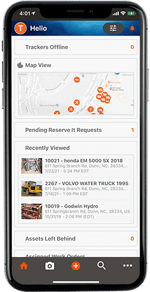

- Telematics Systems for Asset Tracking. Asset tracking allows you to monitor large and small equipment with GPS, Bluetooth, QR, and safety cameras. In addition to monitoring assets, utilization tracking lets you to keep tabs on equipment hours, so you can begin effective preventative maintenance instead of eating the cost of big repairs.

- GPS Maps. GPS tracking and Bluetooth technologies can be integrated into worksite equipment. This allows you to see the whole picture about what machines are working on your project in real-time on digital maps. Not only that, employees and managers can access this information from their phones or tablets, improving accountability and reducing wasted time looking for lost supplies.

- Geofences. A geofence is a virtual perimeter around a defined area, preventing theft and allowing you to designate danger zones. Implementing a geofence can also improve cost efficiency, as you can track the specific location of equipment within a jobsite.

- Dashboard cameras. Safety cameras protect drivers and allow businesses to improve safe driving practices. Also, the GPS and telematics functionality of dashcams give managers a clear picture of vehicles' location and maintenance needs.

- Self-driving heavy equipment. Tesla isn't the only name in autonomous vehicles. The construction industry is starting to see the impact of driverless equipment.

- Employee worn technology. Everything from pressure-sensing boots to AR glasses. "Wearables" can keep your teammates safe and increase productivity.

- Off-site construction. Off-site construction introduces assembly-line efficiency to the construction world. These systems can reduce waste and improve efficiency.

- 3D printing technology. 3D printing technology is already making an impact. Some are using the technology to construct whole communities of 3D printed homes.

The list of construction technology trends today goes on. Watchful businesses see the impact emerging technology in construction has on their safety, cost, and productivity.

Learn about construction technology for equipment management in our comprehensive guide.

How Does Construction Technology Improve a Jobsite?

Construction managers like to get things done. It's discouraging when a project stalls, and sometimes it’s difficult to regain traction. How can technology prevent this?

Generally, new contech improves one of the following domains:

- Communication. Without good communication, a project will fail. Though most agree communication is foundational, many businesses still grapple with staying in touch and up to speed across operations.

- Organization. If you don't know the contents in your conex box, it's difficult to respond to trials when they arise. As we'll discuss later, new technology in construction focuses on helping contractors and their teams get organized.

- Execution. Finally, a team must execute. Execution includes elements of communication, planning, and organization. However, execution emphasizes the physical and tangible - strong workers, a safe environment, and well-functioning, available machinery.

Construction technology recognizes communication, organization, and execution as the engine that drives a project forward. In the next sections, we explore the practical side of these principles.

Construction Technology and Good Communication

During the Second World War, Axis forces launched a covert operation against the Allies: Operation Greif. The mission? Disrupt and confuse Allied communication.

Military commanders understood that communication is the lifeblood of any operation. If they could disrupt that communication, the enemy would crumble.

The same is true for construction teams. As many would agree, if there’s one place to consider instituting improved technology, it’s communication.

Here are several ways technology has beefed up communications on the construction site:

Here are several ways technology has beefed up communications on the construction site:

- Mobile Apps. Mobile apps combined with asset tracking gives team members the ability to pull out their phones and picture the whole job site. Workers can find equipment, and managers can solve problems in real time. Mobile apps also create transparency that keeps everyone honest.

- Building Information Modeling (BIM). BIM works like an interactive computer 3D blueprint. All members of the team can view the changes in real-time. BIM technology makes it easy for each team member to understand where the project is heading and how their department fits into the bigger picture.

- VR simulation. Virtual reality brings future projects to life. VR allows all construction administrators to communicate with stakeholders, ensuring they are on the same page. Buildings can be virtually constructed, allowing everyone the chance to view the project. Sometimes, businesses pair VR with BIM for an immersive experience.

These are just a few ways construction technologies are bringing communication forward.

Now let's discuss organization.

Advancement in Construction Technology Improves Organization

Calvin Coolidge said: "The only difference between a mob and a trained army is organization." The same is true of construction. Disorganization is the enemy of efficiency. So it’s no surprise that a disorganized jobsite creates waste, rising costs, and hazardous work conditions.

Here are several ways construction technology improves organization:

- GPS equipment tracking. GPS technology is simple to install. Many companies offer rugged, durable tracking equipment built for construction sites. Instead of playing musical chairs, GPS tracking lets you move equipment from site to site intelligently.

- Cost forecasting. Planning for the next project is as serious as managing the present. For this reason, modern construction software allows you to collect your data, ensuring you know if you have the equipment, the time, and the staffing for your upcoming project.

- Telematics. Modern businesses don’t wait for personnel to alert them that a vehicle is having engine trouble. Instead, they implement telematics systems that use GPS and cellular signals to send vehicle information directly to them. With innovative telematics solutions, managers can monitor heavy equipment engine hours from the office and schedule maintenance when needed.

Alright, let’s explore how construction technology improves operational execution - in the office and the field.

Examples of Construction Technology Improving Execution

Labor shortages, job site injuries, broken equipment - these are common ordeals. In 2019, OSHA reported that one in five workforce fatalities were in construction. Amid the turmoil, workers and managers have called for safer and more predictable working environments.

As a result, technology has focused on advancement in productivity without compromising safety.

Here's how:

- Improved Operational Efficiency. Technology aids in the productivity and efficiency of employees at all levels and in all roles in a construction business. From eliminating double work to shortening the time it takes to get what you need to improving communication across business units, construction technology is there to help contractors get more done in less time and dedicate more of their focus and energy on tasks that help them execute business winning activities.

- Theft Prevention and Safety. Through the use of geofences, GPS tracking, and safety cameras, an alert can be sent to managers if an employee or piece of equipment leaves the designated boundary. Also, this same technology can alert workers to hazardous zones. If one area of the jobsite poses a risk, all workers can be alerted through mobile apps.

- Wearables. Wearables for construction workers include Smart boots, which can detect when a worker has fallen. Smartwatches and wristbands that monitor heart rate and alert workers to unsafe conditions.

- Autonomous Equipment. The Great Recession caused many construction workers to leave the field. Unfortunately, the workforce hasn’t fully recovered and many managers still have trouble finding staff. Thankfully, technology has offered solutions - including autonomous and robotic equipment. While some view this as "replacing the worker," the truth is that autonomous equipment enhances the worker - making them safer, more efficient, and less stressed.

Good planning requires good communication. If you combine these ingredients, you get powerful execution and a team that gets projects done.

How to Implement New Construction Technology

Nobody wants to be a guinea pig. However, people also don’t want to stand in the way of progress. So, what do you do? It’s natural and often wise to take caution when contemplating “trends.”

With that said, one thing is sure: construction technology isn't a transient trend. It’s here, it's growing, and it’s helping contractors around the world.

AI-Robots and pressure-sensing work boots are an ambitious goal. However, with construction technology, you don't need to sink or swim. It's perfectly reasonable to wade into the waters and see what works for your business.

For all project managers and anyone curious about adopting new construction technology, here are some starting points:

- Start slow. Instead of going straight for high-powered robots, consider a modest approach. For instance, start with something you know will solve a problem, like asset tracking, which reduces theft and often lowers insurance costs.

- Ask questions. Construction companies need construction-based technology. Though some large businesses will target construction with their products, many don’t understand the complex needs of the construction world. So, look for services that specialize in construction.

- Request a demonstration. Just like uniforms and tuxedoes, some construction technologies will fit your business better than others. If you can, try different things. Your business may be strong in tracking equipment but need a boost in data collection and organization.

Construction technology is here, and it’s helping many businesses overcome obstacles and accomplish their goals.

How Construction Technology is Helping Real People

Let's zoom out for a moment. To appreciate how emerging construction technology makes changes for the better, we explore real-world examples of how contech has made a difference.

Here are three stories highlighting the benefits of new construction technology:

- Northern Construction, Massachusetts. Northern Construction, a company with over 700 pieces of equipment, implemented asset utilization tracking, allowing them to move equipment to areas of the most need without wasting time and fuel.

- E-Z Construction, Kentucky. E-Z Construction found benefits in the use of geofences. Separating areas of a jobsite allowed them to pinpoint equipment hours.

- West Bay Landscape, Florida. West Bay uses technology to monitor the maintenance needs of its trucks. When a piece of equipment needs to retire, they have the data to back the decision.

These are just a few examples of the direct impact contech is making.

Final Words on Construction Technology

Construction technology works to enhance the skilled worker, not replace them. Contech is trying to hit the biggest targets - better communication, streamlined organization, and flawless execution.

The goal: Higher productivity, lower costs, and a safer jobsite.

Construction management and planning is a tough job. Similar to the chess master or the military leader, project managers and executives are always making difficult decisions. Technology can't solve every problem yet, but it can provide the information and resources to keep your construction company sharp.

Curious how construction technologies can boost your business? Book a demo and discover the benefits.

About Austin Conti

As CEO and Co-Founder of Tenna, Austin leverages his international experience in construction operations for civil, building, and energy projects with The Conti Group, which has built successful, reputable businesses that make a positive impact on the world in construction, engineering, renewable energy, real estate, technology, and biotech. His passion for entrepreneurship led him to create a construction technology platform built on over a century’s experience from The Conti Group.