Strong equipment management software can transform a construction business. However, good construction equipment management is difficult to support and requires careful planning and execution.

Intuitive equipment management software lays the groundwork for a coordinated construction fleet. Amid supply shortages, rising costs, and a strained labor force, now is a great time to reevaluate equipment management. Often, companies are unknowingly tossing time and money into the gutters. Good software combined with dedicated people can have a truly positive impact on a construction business.

This discussion will highlight the inherent struggle of managing a construction business. Then, we’ll uncover how to choose good construction equipment management software. Finally, we’ll point to the benefits of a tightly managed construction business.

The Juggling Act of Equipment Management in Construction

Anyone in the business knows that construction management is a juggling act. The construction managers and their team aren’t simply “monitoring a construction team.”

They’re tracking heavy equipment, monitoring small equipment, scheduling maintenance, establishing theft deterrents, and ensuring that employees and vehicles are kept safe. And, often, all these tasks must be performed simultaneously for multiple jobsites.

As it happens, not everything always goes smoothly. Sometimes, equipment breaks down, communication falters, and plans change. For contractors and construction business owners, it can seem like a domino effect.

When a vehicle malfunctions, one site must be backfilled with a vehicle from another site, leaving the first site without functioning equipment. All this leads to delays, unnecessary downtime, and negative company morale. Not to mention the unexpected costs and the inability to make accurate bids.

Some may be thinking: I have a construction material management program, but I still have these problems – aren’t problems and delays just part of construction? Doesn’t everyone have problems? While no business is immune to all setbacks, some construction businesses are managed better than others.

Construction Equipment Management Solutions

There are several key components to good construction equipment management. As you’ll see, these various pillars work to uphold the others. Instead of setting up dominos, only to have them all come tumbling down, good construction management builds an interwoven unit, where even if one unit should falter, the other units have their back.

Here are a few principles that positively affect construction management:

- Visibility. You can’t manage what you can’t see, and good construction management starts with getting eyes on all your assets and employees – this can drastically increase the ability to manage a fleet.

- Standardization. Everyone within the company should know their expectations, and nothing replaces principles such as strong personal leadership, mutual respect, and accountability.

- Strong equipment management software. Strong software provides a headquarters for all others forms of equipment management. Automated equipment management systems branch off good software and technology. As we go forward, strong software is the focus of this article.

In the next section, we’ll define construction equipment maintenance software, and discuss why it changes the game.

What is Construction Equipment Management Software?

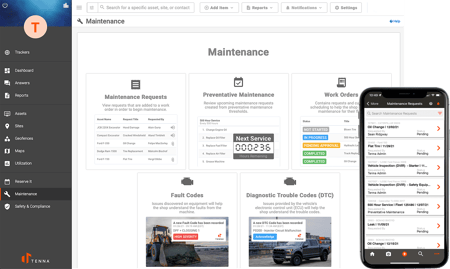

Construction management software is a digital system that acts as a framework for the subcategories of management. Like software for managing employee scheduling, time clocks, or training, construction equipment management software allows you to see the status of all your assets.

In the past, it was common for businesses to use whiteboards and simple pens and paper to track the location of their equipment, maintenance, and costs. However, now all this has been moved to the digital world, allowing the same information to be accessed from an app on a smartphone, tablet, or laptop.

And it’s not simply a move to the digital world. Good equipment management software means easy communication across platforms, and that managers can track their assets in real-time. There is no guesswork.

However, not all equipment management software is created equal. One of the differences between a highly effective construction business and a struggling business is that a highly effective business pays attention to the details.

You don’t just need equipment management for your construction business, you need the right equipment management. The same is true for software. You won’t achieve stellar results from just any software. You need the right fleet management software.

Let’s talk about what makes good equipment management software, then we’ll discuss the many specific benefits.

How to Find Quality Construction Equipment Management Software

Construction management software and automated equipment management systems are designed to give contractors a wide view of their business. However, it can also put them on the worksite, on a vehicle, or in a warehouse. Equipment management in construction requires good software to function as a central hub, connecting the equipment monitoring sensors.

But before we talk about how construction software can help a business; we need to discuss the components of good construction management software.

Here are several markers of good construction software:

Let’s look at these factors in greater detail.

Find Software Designed for Managing Construction Equipment

Not all software that is marketed to construction companies is truly designed for construction companies. There can be times when a company chooses to market its software to a construction team when the software was originally designed for a different field.

This software can often have clear gaps when applied to the construction field, forcing companies to augment the software with outdated practices – this is counterintuitive. Instead of getting the benefits of both, companies get the negatives of both.

Non-specific software often isn’t built to handle the demands of a modern construction company, leaving the company attempting to get by with subpar software, while still needing to cover their bases with whiteboards, spreadsheets, and disintegrated communication.

If the construction company can find software designed for construction, then they will be able to reap the full benefits of construction software.

The first step is finding construction equipment management software designed for the industry, the next step is ensuring that software has the required features for a multifaceted construction company.

Find Construction Software That Integrates

The next goal is to find construction fleet management software that allows a business to be fully integrated. For more on integration, read this article on leveraging integrations to improve daily workflow.

At its core, integration is all about separate entities communicating as one. This could mean that different software platforms can share information, or it could mean that various parts of a construction business can all communicate on the same platform.

For example, an integrated construction company will allow the maintenance department, the construction crew managers, and the contractors to all speak clearly with each other. It could even mean entities like the HR department can easily see and share data when needed.

In a large construction company, integration will save time, keep partners informed, and lead to smoother jobsites. Ensure that the construction software you choose allows for a broad range of integration. The last thing you want is a wall between two different software platforms in your company – this just leads to wasted time and confusion.

Find Software for Light and Heavy Equipment Management

The final quality to look for in good equipment management software is that it is a one-stop shop for all your fleet management needs. This means the software can handle heavy equipment, vehicles, and even small tools.

You may find some software that’s mainly designed for heavy equipment and doesn’t have the tools or features to handle smaller items, such as hand-used power tools. Why is this an issue?

Just imagine that you have different management software for each type of tool. One software for the skid steers, one software for the fleet vehicles, one for the hand tools – before you know it, you’ll need tracking software for the software itself. This isn’t ideal. And why it’s critical to find equipment management software that will encompass your entire range of construction tools, be it hammers or cranes.

Now that we’ve determined the component of good equipment management software, let’s look at some of the benefits of good software for equipment management. We’ll also touch on some of the dangers of not looking at good software.

The Benefits of Good Construction Equipment Management Software and Systems

Construction companies are facing some of the more volatile times in the industry. There have always been difficulties, but lately there have been some particularly rare challenges. At a time when demand for new construction is high, there have been concurrent supply shortages, not to mention an exodus of the workforce, new pressures to eliminate waste, and overall economic uncertainty.

Many construction businesses will adapt and weather these storms, as they have always done. However, some will be left behind. There is no better time than now to consider the deepest aspects of how to manage your construction company - and the benefits of good equipment management software. It’s also wise to be realistic about the dangers of ignoring advances in construction technology.

The benefits of fully integrated construction management software:

- Reduce expenditures and improve productivity

- Bolster safety and prevent theft

- Optimize maintenance

- Create a competitive advantage

Now we’ll look at each of these benefits more thoroughly.

How Equipment Management Software Reduces Equipment Costs and Improves Productivity

Good construction management software will help teams avoid wasted time. Construction software helps managers know where all their assets are, so they can make the best decisions about how to do a job. This real-time data is one of the reasons software is superior to manual methods.

Idle worker time can create a huge expense. While there are times when this is unavoidable, in the past, there was no way of knowing if a worker was active or not. With construction management software, you can see what’s happening on the jobsite with a single glance at your smartphone.

The same is true with equipment. In the past, there was equipment zigzagging from jobsite to jobsite with no clear purpose. But with good equipment management software, contractors can carefully strategize the placement of their assets.

Managing Construction Equipment Improves Safety and Prevents Theft

There’s no doubt that construction managers worry about the liability of vehicle accidents and worker injuries. But it might also be a surprise to learn that software has any connection to safety on the job. But it does.

For one, good construction software allows for remote heavy equipment monitoring in real-time, ensuring that no unnecessary trips are made (or unneeded hours on the road) and that drivers of long distances are stopping for adequate rest.

Second, equipment management software allows managers to stay on top of daily inspection forms, ensuring that employees complete these forms thoroughly and on time and that any issues are corrected. Digital check-in forms can directly plug into equipment management software, ensuring proper maintenance. Which is another benefit of good equipment management software.

Finally, we can't discount the rising dangers of equipment theft. Good software always keeps eyes on the equipment, reducing equipment theft and loss.

Better Vehicle Maintenance with Good Equipment Management Software

Good equipment management software will also ensure that maintenance is performed regularly. Good software will not only let businesses closely monitor equipment utilization, but it will also be able to receive updates from specific vehicles, leading to more timely maintenance.

Heavy equipment sensors and vehicle telematics can transmit information directly to equipment management software, allowing construction managers to move away from reactive maintenance and move toward proactive and even predictive maintenance.

To learn more, read our article on equipment maintenance for heavy equipment.

Remote Monitoring Equipment Management Software Provides a Competitive Advantage

The last thing to keep in mind is the benefit when it comes to winning work and staying ahead of the competition. Good equipment management software can give construction teams an edge, as they can bid more accurately and provide realistic timeframes.

When a construction company has its ducks in a row, they don’t need to worry about underbidding, nor do they need to be concerned with constantly updating their budget. Those that have their equipment well managed will complete projects faster with higher quality.

The competitive edge is the sum of all the other benefits we’ve listed. As we’ve mentioned above, some companies will resist the shift to better technology, and likely lose a step. There have always been those who distrusted new tech, and this is understandable to a point, but it’s if it boils over into an unhealthy resistance to all new ideas, it can lead to a competitive slip.

Let’s look at several tips for wielding the full power of equipment management software.

Top Tips for Leveraging Construction Equipment Inventory Management Software

Before we go, let’s cover a few ways you can leverage your equipment management software for the best experience. We have already outlined what to look for in software for managing equipment, but now we’ll discuss how to make that software more effective.

Here are three tips for using your equipment management software:

- Use fleet management tracking tools. Tools such as GPS trackers will greatly enhance your ability to manage your heavy equipment. For lighter equipment, smaller trackers such as Bluetooth trackers and QR trackers will help ensure no hammer is unaccounted for.

- Implement geofences. A geofence is a digital map of a jobsite. It’s like an invisible fence, and it can be easily programmed to alert managers when a tool is moved from the jobsite. Geofences help prevent equipment theft and allow managers to easily track the tools between multiple jobsites.

- Use digital equipment inventory management software. Moving away from paper check sheets and toward digital forms can greatly improve equipment management. These digital inspection forms can easily include pictures for contexts, and they are submitted in real-time, preventing any fudging on the part of rushed employees.

These are just a few ways you can ensure you get the most out of your equipment management software.

Key Takeaway on Construction Fleet Management Software

During tumultuous times, making the decision to improve equipment management is prudent. Better equipment management saves money, reduces wasted time, and improves the safety and security of the entire construction fleet.

Good fleet and equipment management software can give you a competitive edge, improve company visibility, and lead to smoother jobs and fewer roadblocks.

Contact Tenna to discover how their equipment management software can transform your construction business. A Tenna representative would be happy to listen to your needs, answer any questions, and supply a no-stress demonstration.

About Jhan Mughal

Jhan has been helping construction companies adopt Tenna technology for 5+ years. As Lead Customer Success Manager, holding a degree in supply chain management, Jhan looks at ways to help contractors improve their standard of operations for a successful Tenna rollout. He focuses on helping companies streamline and improve processes to enhance profit and productivity.