“Asset Tracking” is a common term used by many contractors looking to track the location of their different asset types. Lost and misplaced assets are a real industry problem but it’s only one piece of the overall operational puzzle and only one of many opportunities to recoup unnecessary spending on assets and on people hours.

Owning and managing a mixed fleet of assets is complex, and it goes way beyond each asset’s physical location. That’s why it’s imperative that when considering an equipment tracking system for your business, you should be thinking about a more comprehensive equipment management solution that is focused on the whole operational picture; not just tracking.

Think about the ways you can make your operations and the people across your entire team more efficient. Saving money on fuel and unnecessary rentals, increasing utilization, reducing maintenance headaches and safety issues, streamlining dispatching and more are all solutions your business should be looking for that go deeper beyond tracking.

We’ll cut right to the chase. Here are our top reasons how construction-specific, operations-focused equipment management systems bring value to construction businesses.

Value Today

Equipment management systems bring value in the field, shop and office and connect these roles that typically work in silos. They bring value to different members of your team across the many different roles in a construction business. They provide value for everyone, and their effects permeate throughout the business, connecting those roles that were traditionally stuck on islands.

This section goes deep into their value around the following:

- Time and efficiencies

- Cost savings, ROI and profitability

- Increased competitiveness

Time and Efficiencies

At the most basic and foundational level, equipment fleet management saves your people time. Time is a valuable commodity and non-renewable resource.

How does equipment management save time? It saves people time in the field, in the office and on the go by letting you quickly access needed information that would normally require extra hours searching for. Calling someone up for information? Trust us, it will be quicker to access it yourself in your equipment management app than calling your co-worker, calling him back when he doesn’t answer, leaving a voicemail, missing his return call, catching up to shoot the breeze, waiting for him to retrieve your data, getting it back, requiring edits, and so on. Why spend the extra time? An asset management system will pay for itself ten-fold if its saving time for your personnel every day.

Equipment fleet management systems help personnel get work done faster when not spending time on gathering intel from multiple sources in multiple formats.

Bonus win: reducing stress caused by time constraints inherently leads to better workplace satisfaction and performance. When you implement a solution that makes the day to day lives of your employees easier, they will perform better and ultimately be more productive. This is a benefit for them that translates to a benefit for overall business success.

In today’s challenging construction labor market, this is more important than ever. Employees want to work for a company that is performing well and has tools in place that will make their days easier, safer and ultimately more fulfilling. Operational efficiencies resulting from equipment management systems (across the many roles and levels these systems impact) lead to an easier workday, happier staff and more productive workdays.

This applies to folks in the field, as well as in the shop and the office. Reducing manual processes through automation and having confidence (vs. confusion) that they are working with accurate data helps save time and facilitates better decision making at all levels of the organization.

It would be remiss not to touch on some of the challenges around adopting a new system, as behaviors are often hard to change, but when your team realizes the value that an asset management system has on their days directly, it improves buy-in and overall adoption. This leads to operational improvements, and growth to the bottom line.

Cost Savings, ROI and Profitability

Saving time and increasing productivity are valuable efficiencies that lead to a positive ROI on your investment in equipment management technology and result in overall increased profitability. But before it trickles that far, there are some more immediate cost saving benefits to consider.

Equipment management systems create opportunities for direct cost savings in multiple areas including reduced breakdowns and repair needs with better maintenance, fewer unnecessary rentals, improved fuel consumption and less waste, all which directly translate to the bottom line. Avoiding one single unnecessary rental or machine breakdown or avoiding a claim and related legal fees is typically enough of a savings to cover the annual cost of an equipment management system itself. The truth in construction is that these situations happen often, and an equipment management system can help prevent these costs multiple times, compounding your potential savings. That’s immediate ROI, and ongoing savings, that translate directly to profitability.

Equipment management systems create opportunities for direct cost savings in multiple areas including reduced breakdowns and repair needs with better maintenance, fewer unnecessary rentals, improved fuel consumption and less waste, all which directly translate to the bottom line. Avoiding one single unnecessary rental or machine breakdown or avoiding a claim and related legal fees is typically enough of a savings to cover the annual cost of an equipment management system itself. The truth in construction is that these situations happen often, and an equipment management system can help prevent these costs multiple times, compounding your potential savings. That’s immediate ROI, and ongoing savings, that translate directly to profitability.

Let’s consider a real money example.

For the cost of a field engineer’s annual salary, you purchase an equipment management system with features and functionality that will save you tenfold in multiple areas of your operations that benefits multiple teams.

For what it would cost you to replace the undercarriage of an excavator, you’ve purchased hardware that feeds into a system allowing you to accurately capture the hours or miles of all your assets on wheels or with engines. Think about how much it costs you to have multiple field engineers running around your jobsites manually logging equipment hours, manually entering that info into a spreadsheet, running reports with potentially faulty and already outdated data, etc.

Add up all those man-hours for all your field engineers across all your jobsites. To implement an equipment management system to automate that process for the cost of just one of those employees, you’ve freed up that many man hours across the existing staff to put towards other focuses, allowing you to gain massive productivity elsewhere.

At the end of the day, using an equipment management system to save immediate costs and ultimately reduce your total cost of ownership is immensely valuable for putting money back into your balance sheet to reinvest in your business.

Increasing your Competitiveness

Technology is changing the way your competition does business. By now, you can guarantee that your competitors are beginning to leverage at least basic forms of the construction technology options available in today’s industry.

In fact, according to a survey and corresponding study published by Autodesk in late 2021, more than 80% of respondents reported an increase in the project data their organizations are creating from construction technology over the past three years. Almost half experienced more than a 50% increase. This suggests that businesses are increasingly adopting and leveraging technology in their day-to-day operations. According to a 2022 Procore ROI Report, Construction technology investor funding reached a record $2.1 billion in 2021––more than a 100% increase from a year ago, which indicates that construction technology is here to stay. Use of construction technology for operations is a trend contractors will want to become familiar with.

Yet another area of value when you adopt an equipment management system, specifically, as an operational tool that goes beyond tracking is that it keeps you current and gives you a leg up on the other contractors who onboarded a simple telematics system and think they are set.

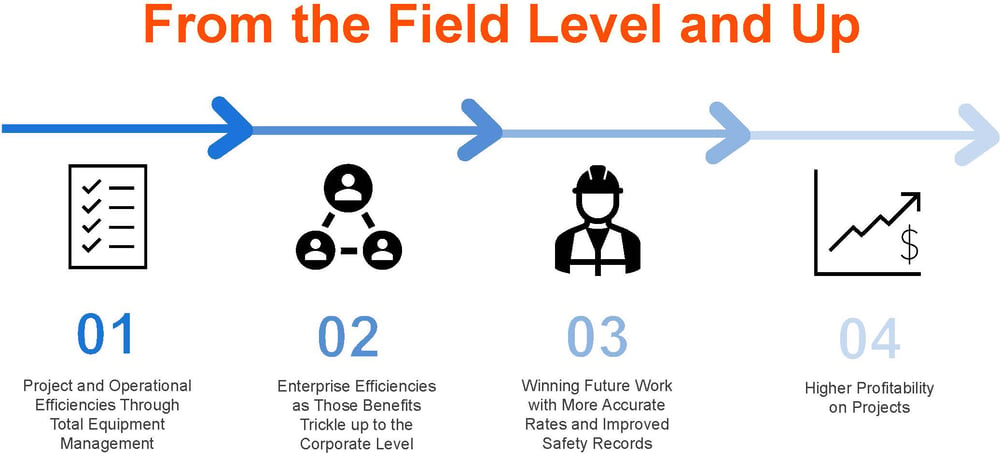

From the field level and up, project and operational efficiencies through total equipment management leads to enterprise efficiencies as those benefits trickle up to the corporate level which then leads to winning future work with more accurate rates and improved safety records, and ultimately results in higher profitability on those projects.

When you leverage an equipment management system that monitors utilization, you have a better basis to build more accurate billing rates, ultimately leading to more informed bid rates that you submit to win future work. When you know what it really costs you to build a job, you can be more competitive at bid time and become more profitable in the execution of those jobs after mobilizing and breaking ground.

When using an equipment management system to bolster your operations, you can efficiently:

- Bid projects with accurate utilization rates from historical data and build your library bids with more accurate data for future bidding efforts.

- Capture accurate utilization of the assets on each jobsite to keep fueling the bidding engine

- Facilitate better forecasting with visibility into the schedules of your existing projects and their resource needs so you can secure the assets you need for your critical path items in advance, and spot maintenance gaps or rental needs early to avoid conflicts.

- Mobilize and deploy available and well-maintained assets and associated labor and crews to kick off projects with resource management and dispatching

- Incorporate planned maintenance downtime and supplement jobsites with replacement assets when maintenance is needed to avoid productivity shutdowns and schedule slips

- Inspect assets for safety and compliance before operation to avoid maintenance issues, malfunctions, safety risks or violations.

- Integrate key asset data with other systems your business relies on to keep teams connected.

- Keep your team productive with the assets they need to get the job done.

The cycle repeats. All these operational efficiencies repeat to continue to aid in winning and executing work for ongoing business growth and success.

Equipment Management System Features and Values

Some quick value highlights that different features within an equipment management system can bring to your business and operations include:

- Utilization. Knowing accurate utilization benchmarks and thresholds can help you better estimate utilization for other machines and new machines you add to your fleet. This helps maximize their useful life and earns you an ROI based on your ownership and operating costs.

- Maintenance. Staying on top of preventive maintenance can drastically improve your assets’ functionality and extend their useful life while minimize excessive repair costs which weigh down your ownership and operating costs.

- Resource Management, Dispatch and Schedule. Knowing what you have available, masterfully yet easily allocating it between projects and maintenance downtime and maximizing the utilization of your owned assets impacts excessive rental costs and helps you optimally use the assets you are already carrying on your balance sheet.

- Fuel Management. Whatever the cause of it, curbing your idling will cut your ownership costs. Leveraging telematics data to get a handle on your idling behaviors and curbing fuel theft can have a tremendous impact on your TCO.

- Safety & Compliance. Lowering your risk of malfunction and safety issues with proper and regular inspections while lowering your insurance premiums with documented safety monitoring programs is a double cost benefit for your TCO.

- Asset Billings. Having your cost and earnings information automated and available can help you identify when costs are being exceeded or find opportunities for cost cutting or earnings to balance out your TCO.

- Integrating your equipment management data (more than just location) into other systems your business relies on, such as your ERP or accounting systems or project management programs, is invaluable for keeping your teams connected and informed with automated, reliable information.

When Looking for a Solution….

Look for a total equipment management solution that is construction focused and goes far beyond simple telematics. Look for a system that leverages that tracking data for multiple other purposes and provides construction-focused solutions you need to other operational and equipment related challenges your team and your business have.

At the end of the day, you get what you pay for. When you purchase a tracking system, you get potentially decent tracking data. However, this is often impacted by unreliable hardware not built for construction environments, and very likely it’s delivered in a data dump that you then need to sort through to understand and work with.

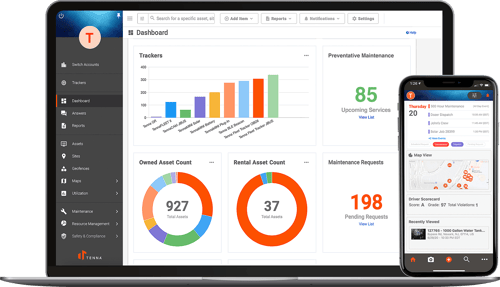

Systems like Tenna can make a big impact on bringing value to your business in terms of time savings, increased productivity, cost savings and efficiencies and overall increased profitability. Other tracking providers may say these things too, but as a construction-focused partner to other contractors, the industry trusts that we do it. This is evidenced by multiple contractor testimonials and reviews, and industry rankings across other tracking providers.

Future Value of Equipment Management Systems

Asset management is becoming a standard practice in today’s modern industry because of the many values it brings as already highlighted. But what about future value? Where can the value of equipment management continue to be seen down the road?

Construction technology, particularly in the equipment management space is becoming more of a norm and more heavily adopted by construction businesses as we continue to evolve to a more tech-focused and tech-driven work environment. Today’s systems will continue to evolve as well as time goes on.

Construction technology, particularly in the equipment management space is becoming more of a norm and more heavily adopted by construction businesses as we continue to evolve to a more tech-focused and tech-driven work environment. Today’s systems will continue to evolve as well as time goes on.

Not only will the existing value of equipment management systems continue to benefit businesses over time for the reasons emphasized earlier, but there are potential areas where it can provide benefits in other ways in the future. For example, we may see:

- An increase in trust from your customers that you know what you’re doing in the field and that you are working efficiently.

- Your equipment management KPIs become part of your proposal requirements to win work.

- Metrics in your safety program, that you’ll be able to deliver straight from your equipment management system, will become a point of interest to your clients.

- More ways of integrating data as integrations with other software programs become more sophisticated

Conclusion

Deploying a construction technology system for managing your assets brings all of the above benefits to life for your business – are these efficiencies valuable to you?

Asset Tracking is only the start. Don’t just stop there. Thoroughly managing your assets is the means to the end for real value in your business operations and profitability. Tenna takes you beyond tracking. Contact us today to reap the benefits.

About Austin Conti

As CEO and Co-Founder of Tenna, Austin leverages his international experience in construction operations for civil, building, and energy projects with The Conti Group, which has built successful, reputable businesses that make a positive impact on the world in construction, engineering, renewable energy, real estate, technology, and biotech. His passion for entrepreneurship led him to create a construction technology platform built on over a century’s experience from The Conti Group.