For years, contractors have relied heavily on their ERP as their single source of truth. More recently, contractors across the industry are adopting equipment management programs into their businesses to help them gain better visibility over their operations and the costs associated with the high value equipment assets they rely on to perform their projects. Because contractors are adopting more and more technology into their business ecosystems in general, integrations have proven to be something they care greatly about to better connect the systems they have invested in and truly leverage and optimize the data their programs can offer. Integrating their equipment management platforms to share accurate data with their trusted ERP is a game changer for modern construction businesses and is becoming a “have to have” vs. a “nice to have” in today’s rapidly advancing industry.

Tenna’s partnership with Trimble-Viewpoint allows for deep integrations with ERP products widely used across the industry to simplify equipment data flow and analysis for construction accounting and finance teams. Read on to learn more about this key partnership for contractors.

Tenna + Trimble-Viewpoint Partnership Overview

With multiple integration offerings across Viewpoint® products, Tenna’s partnership with Trimble-Viewpoint, the industry-leading construction ERP solution provider, empowers construction finance professionals to see and autonomously capture equipment data within a single location.

With multiple integration offerings across Viewpoint® products, Tenna’s partnership with Trimble-Viewpoint, the industry-leading construction ERP solution provider, empowers construction finance professionals to see and autonomously capture equipment data within a single location.

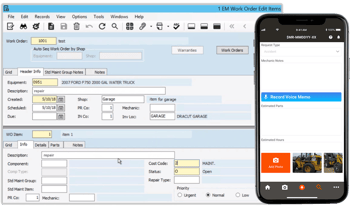

As part of their partnership, Tenna and Trimble-Viewpoint work together to make the lives of construction business owners and their teams simpler through integrations between Tenna and multiple Viewpoint ERP products facilitated by Ryvit including Viewpoint® Vista™ (hosted or within Viewpoint® One™) and Viewpoint® Spectrum™.

Existing data exchanged between Tenna and Trimble-Viewpoint products includes individual pieces of equipment, their location and utilization information (hours/miles) as well as jobs and other sites. Opportunities for additional data connections and integrations with additional products continue to be explored and expanded, such as the recent maintenance work order integration between Tenna and Viewpoint® Vista™.

“The partnership between Tenna and Trimble-Viewpoint is further evidence of an industry-wide shift towards a shared commitment to accelerate the use and adoption of technology in construction,” says Tom Stemm, CEO at Ryvit.

What Makes This Partnership Different?

Tenna’s platform for construction equipment management is nearly identical to what Viewpoint products are to ERP: construction focus meets single platform. These systems together are a natural, synergistic and complimentary match and are both critical tools that contractors rely on to run their businesses. These integrations solve an important contractor need.

With their products integrated and a unique overlap in their target market focus, both Tenna and Trimble-Viewpoint continue to live at the crux of a contractor’s technology ecosystem by providing all the solutions and tools contractors need to effectively manage and run their businesses.

“The field, shop and office are all frustrated today by a lack of construction-focused systems and having to use multiple systems with difficulty that leave their data in silos and not integrated with other construction technology,” says Russ Young, Chief Business Development Officer at Tenna. “These problems are moving the ball towards better automation and fueling a fire among contractors to demand integration of the business systems they’ve invested so much time and money into. This key partnership between Tenna and Trimble-Viewpoint provides greater value to the construction industry by centralizing key business systems that contractors rely on while making it easier for them to leverage those systems most effectively.”

“The field, shop and office are all frustrated today by a lack of construction-focused systems and having to use multiple systems with difficulty that leave their data in silos and not integrated with other construction technology,” says Russ Young, Chief Business Development Officer at Tenna. “These problems are moving the ball towards better automation and fueling a fire among contractors to demand integration of the business systems they’ve invested so much time and money into. This key partnership between Tenna and Trimble-Viewpoint provides greater value to the construction industry by centralizing key business systems that contractors rely on while making it easier for them to leverage those systems most effectively.”

Why the Tenna + Trimble-Viewpoint Partnership Matters to Contractors

Tenna’s partnership with Trimble-Viewpoint makes a big impact for the bottom line of their current and future joint contractor customers. This partnership solves a multi-million-dollar business need for contractors, making it easier for them to see where they are bleeding capital and helps them get better control over how they leverage their current resources to ultimately benefit the books. Knowing more by seeing data clearly within the integrated systems and being able to better account for equipment costs and investments allows contractors to take strategic actions to own less, rent less, better maintain and optimize what they have, and deliver work more with less downtime, which leads to increased project margins and higher revenue. The power of this automated data flowing from Tenna into Viewpoint and Trimble products gives contractors, and specifically the accounting and finance teams, the actionable insight to accomplish this.

Ready to Integrate your ERP with your Equipment Management System?

For Tenna, the multiple integrations within this partnership are another huge step in their mission to provide integration capabilities with key construction software systems that contractors heavily rely on. Integrations are an ongoing and growing need for contractors as they continue to add additional technologies and software into their business ecosystems; Tenna commits to staying ahead of this demand to remain the best construction-focused, integrated equipment management solution for the industry.

Contact Tenna today to learn more about how to integrate your equipment and maintenance data into your Viewpoint® ERP.

About Russ Young

As Chief Business Development Officer for Tenna, Russ oversees the growth strategy for the organization by working with sales, partners and customers to ensure success. Russ brings two and a half decades of experience from Google, Amazon, Oracle and FMI in best practices for technology strategy, selection and adoption. He applies his knowledge from these organizations to build awareness and provide thought leadership to the construction industry. He emphasizes the importance of technology and picking the right tool for the job.